In industrial enterprises, the most common poisonings are:

chlorine, ammonia, carbon monoxide, hydrogen sulfide, aniline, metal aerosols, gasoline, benzene, nitrobenzene, arsenic, nickel and mercury.

Kosarev V.V. and Babanov S.A. in the “Handbook of Occupational Pathologists” (2011) and the guide for doctors “Occupational Diseases” (2012) call poisoning of the body when exposed to dust, chemical factors, causing not only intoxication, but also occupational diseases.

Moreover, acute occupational diseases and intoxications that arise suddenly after a single exposure to an unfavorable factor during one work shift should be considered poisoning.

Chlorine poisoning

Chlorine belongs to the group of halogens.

It is a yellow-green gas with a pungent, unpleasant odor. Under a pressure of 0.6 MPa, it easily liquefies at ordinary room temperature; it is an oxidizing agent and is chemically very active. During World War I, the Germans used liquefied chlorine as a weapon of mass destruction; Nowadays, chlorine is not used during combat operations. It is widely used in the production of chlorine-containing organic compounds, in the pharmaceutical industry, in the pulp and paper industry for bleaching pulp, paper, and also for bleaching fabrics. Chlorine compounds are widely used to disinfect water, wastewater, waste accumulations, and sewage. Chloramines are used in the production of preparations for sanitation and hygiene needs, in the aniline dye industry, for decolorization and deodorization of water, and also as oxidizing agents, herbicides and defoliants.

Chlorobenzene (C6H5Cl)

used for the production of phenol, insecticides, medicinal substances, rubber, dyes, herbicides, non-ferrous metals and as a solvent and catalyst. Chlorine poses a serious danger if solutions of its compounds are accidentally ingested or inhaled or come into contact with the skin. It is also a threat to workers and employees during natural disasters and industrial accidents where chlorine and its compounds are used. In domestic conditions, there are cases of intentional or accidental ingestion of chlorine-containing detergents and cleaners.

Prolonged work with inhalation of low concentrations of chlorine from the air of work premises leads to chronic poisoning of the body. Already at a concentration of chlorine in the air of working premises of 0.001-0.006 mg/l a person feels a sore throat, and at a concentration of 0.1-0.2 mg/l staying in a room for half an hour is dangerous to health; at a concentration of 10 mg/l of air within one minute death occurs in 50% of victims.

When inhaled, chlorine reacts with moisture in the mucous membranes of the eyes, nose and oropharynx, forming hydrochloric acid and oxygen, which damage the mucous membranes and irritate nerve receptors. In response to irritation of nerve receptors, spasm of the larynx, bronchi, respiratory distress, and cardiovascular activity appear.

Clinical forms of acute chlorine poisoning

The course of chlorine damage occurs in mild, moderate, severe and lightning-fast forms of severity.

A mild form of acute poisoning is characterized by the absence of a primary reflex reaction. But sometimes victims are tormented by a dry cough, pain in the eyes, lacrimation, and sore throat. Rarely, pulmonary edema develops in cases of respiratory and heart failure. When providing pre-medical and medical care to victims, these symptoms disappear within 1-2 days.

In case of acute poisoning of moderate severity

There is a headache, a continuous dry, painful cough, chest pain, burning, pain in the eyes, lacrimation, and sometimes dyspeptic symptoms are observed. After an hour, suffocation may occur from spasms of the larynx and bronchi, and reflexive cessation of breathing.

Breathing is restored, but remains shallow, rapid, and cannot satisfy the body’s need for oxygen. Cyanosis of the lips is observed, body temperature rises to 37.5-37.8°C, cardiovascular failure and pulmonary edema develop. When qualified assistance is provided, clinical recovery occurs within 10-12 days.

For severe chlorine poisoning

loss of consciousness, cyanosis, cardiovascular failure, clonic convulsions of the respiratory muscles, reflex spasm of the larynx, and respiratory arrest are observed. Death occurs 5-25 minutes after this.

When high concentrations of chlorine are inhaled, a fulminant form of poisoning occurs; breathing stops due to laryngospasm and cramps of the respiratory muscles. The victim develops cyanosis, suffocation and death within minutes.

For mild to moderate poisoning

Atrophic tracheobronchitis, pharyngitis, pneumosclerosis develop, and pulmonary heart failure may develop.

First aid consists of stopping the entry of chlorine into the body. It is necessary to remove the patient from the contaminated room, provide warmth, a calm atmosphere, warm drinks, and allow him to breathe oxygen. Quick evacuation to a medical facility guarantees a speedy recovery.

First aid:

1) rinse the eyes with a 2% sodium bicarbonate solution or clean water after removing the gas mask; 2) to improve cardiac activity, 1 ml of a 10% caffeine solution or 1 ml of cordiamine is administered; 3) outer clothing that has absorbed chlorine vapors is ventilated, complete rest is created if possible, and victims are warmed up if necessary.

Subsequently, at the stages of medical evacuation, anti-edematous therapy is carried out; providing the body with oxygen; prevention of cardiovascular failure; introduction of broad-spectrum antibiotics to prevent the development of complications.

Victims need strict bed rest, possible irritants are excluded; even at a comfortable temperature, the victim is wrapped up, warmed with heating pads, provided with easily digestible high-calorie food and a drinking regime appropriate to the severity of the injury. If pulmonary edema develops, until it passes, the victim is detained for a week for resuscitation measures and anti-edematous therapy is carried out.

The most common causes of intoxication

As modern clinical practice shows in food poisoning, cases of infection are most often diagnosed by pathogenic microorganisms rather than by chemical or natural toxins. The most typical causes of acute intoxication:

- Escherichia coli . It is found in minced meat, meat and vegetables, whole raw milk and other products that were not washed or processed well enough, or were handled with dirty hands. The problem is characterized by acute pain in the intestines, bloating, high fever and diarrhea. Certain types of E. coli can be extremely dangerous and create the preconditions for extremely severe toxic damage, sometimes even death;

- Salmonella . The main causative agents of infection are eggs, processed chicken parts and other types of raw meat, including domestic animals, for example, reptiles or rodents. The symptoms of poisoning are quite vivid and can last for more than a week with high fever and other unpleasant symptoms;

- Staphylococcus . Bacteria of certain types of staphylococcus release toxins into food at room temperature or other optimal conditions;

- Poisonous mushrooms . A fairly common cause of poisoning is the consumption of personally collected mushrooms, which are unsuitable for food due to the presence of poisons and toxins in them. At the same time, mistakes are made by both beginners and experienced mushroom pickers, so it is advisable to completely exclude non-industrial forms of products from your daily diet;

- Spoiled and expired food . A typical problem that almost always leads to the development of food poisoning is the consumption of food that has not been stored properly or has reached the end of its useful life. In this case, the above-mentioned products can accumulate pathogenic microorganisms, change structurally and create preconditions for severe intoxication.

Carbon monoxide poisoning

Carbon monoxide, or carbon monoxide (CO),

is an odorless and colorless gas formed during incomplete combustion of carbon-containing products (from insufficient oxygen supply). Carbon monoxide is part of a number of industrial flammable gases and is used in blasting operations.

Carbon monoxide is contained in blast furnace, furnace, mine, and tunnel gases. In domestic conditions, carbon monoxide is formed during incomplete combustion of the fuel used in home stoves; a large amount of it is formed during fires. Poisoning occurs at concentrations above 100-200 mg/m3. And at a concentration of 400-600 mg/m3 and a duration of exposure from two to five hours, an acute disturbance of cardiac activity develops.

When surveying 108 students of the Faculty of Education, it was found that 10.91% of them had mild carbon monoxide poisoning due to improper use of stove heating by their parents.

Carbon monoxide, which is more active than oxygen, combines with hemoglobin to form carboxyhemoglobin; it is not able to carry air oxygen in the body, so carbon monoxide poisoning causes tissue oxygen starvation. Carbon monoxide has a toxic effect on brain cells, which is why carbon monoxide poisoning causes severe headaches. When up to 50% of carboxyhemoglobin accumulates in the blood, loss of consciousness occurs, clonic, then tonic convulsions develop.

Carbon Monoxide Poisoning Clinic

With a mild degree of poisoning,

the victim has noticeable pulsation of the temporal arteries, headaches in the frontal and temporal lobes, dizziness, nausea, vomiting, and muscle weakness. There is a feeling of fear, anxiety, impaired coordination of movements, weakened hearing, there may be a short-term loss of consciousness, breathing becomes more frequent, shortness of breath appears, the skin and visible mucous membranes are hyperemic.

Average degree of poisoning

characterized by complete loss of consciousness, clonic, then tonic convulsions appear, temperature rises to 40 C. After recovery, victims may experience psychosis, accompanied by phobias and hallucinations, develop Parkinson's disease, mask-like face, scanned speech, lack of coordination in limb movements. Hemorrhages in the brain and atrophy of the optic nerves may develop.

Severe poisoning

leads to prolonged loss of consciousness; after painful clonic and tonic convulsions, muscle relaxation occurs, collapse develops, breathing becomes shallow, and death occurs from paralysis of the respiratory center.

First aid for carbon monoxide poisoning

It is recommended to take the victim out of the dangerous area, rub the front surface of the chest, inhale ammonia, apply heating pads to the legs, give hot tea and coffee.

For mild cases, complete recovery occurs within a day, and for more severe injuries, a longer period of rehabilitation occurs. We conducted a survey to study the awareness of students of the Faculty of Education about the rules and techniques for providing first aid for carbon monoxide poisoning. The results of the study showed that students are not sufficiently informed about these issues. The following answers were received: providing access to fresh air (44.44%), drinking plenty of fluids (14.81%), drinking milk (7.41%); 33.4% of the students surveyed answered “I don’t know.”

A survey of parents of preschool children was also conducted, who suggested: ventilate the room (24.85%), take the victim to fresh air (15.76%), call an ambulance (20.0%), perform artificial respiration (8.48%) , the remaining 30.91% avoided answering or answered “I don’t know.”

In severe forms of damage, accompanied by collapse and respiratory arrest, qualified medical care is required.

You need to know that the prognosis for carbon monoxide poisoning depends on its concentration in the affected area and the duration of stay in the contaminated room. Even with a low concentration of carbon monoxide in the contaminated area, moderate poisoning can occur, since increased physical activity increases a person’s breathing volume per minute. The prognosis after severe poisoning is unfavorable; usually only half of the victims fully recover.

To prevent carbon monoxide poisoning, employees of the relevant workshops are given special gas masks. In the filter-absorbing box of such a gas mask there is a hopcalite cartridge capable of converting carbon monoxide into carbon dioxide.

List measures to prevent occupational poisoning

Measures to prevent occupational poisonings and diseases should be aimed primarily at the maximum elimination of harmful substances from production by replacing them with non-toxic or at least less toxic products. It is also necessary to eliminate or minimize toxic impurities in chemical products, for which purpose it is advisable to indicate the limits of possible impurities in the approved standards for these products, that is, to carry out their hygienic standardization. If there are several types of raw materials or technological processes for obtaining the same product, preference should be given to those materials that contain fewer toxic substances or the existing substances have the least toxicity, as well as those processes that do not release toxic substances or the latter have the least toxicity. toxicity. Particular attention should be paid to the use and production of new chemicals whose toxic properties have not yet been studied. Among these substances there may be highly toxic ones, therefore, if appropriate precautions are not taken, the possibility of occupational poisoning cannot be excluded. To avoid this, all newly developed technological processes and newly produced chemical substances should be simultaneously studied from a hygienic standpoint: the danger of releasing harmful substances and the toxicity of new substances should be assessed. All innovations and proposed preventive measures must be coordinated with local sanitary authorities. Technological processes using or the potential for the formation of toxic substances should be as continuous as possible in order to eliminate or minimize the release of harmful substances at intermediate stages of the technological process. For the same purpose, it is necessary to use the most sealed technological equipment and communications that may contain toxic substances. Particular attention should be paid to maintaining tightness in flange connections (use gaskets resistant to this substance), in closing hatches and other working openings, stuffing box seals, and samplers. If a leak or release of vapors and gases from the equipment is detected, it is necessary to take urgent measures to eliminate existing leaks in the equipment or communications. To load raw materials, as well as unload finished products or by-products containing toxic substances, sealed feeders or closed pipelines should be used so that these operations are carried out without opening equipment or communications. The air displaced during loading of containers with toxic substances must be removed by special pipelines (air ducts) outside the workshop (usually to the upper zone), and in some cases, when displacing particularly toxic substances, it must be pre-cleaned from harmful substances or neutralized, disposed of, etc. Further. It is advisable to maintain the technological operating mode of equipment containing toxic substances in such a way that it does not contribute to increased emissions of harmful substances. The greatest effect in this regard is provided by maintaining a certain vacuum in the devices and communications, in which, even in the event of a leak, air from the workshop will be sucked into these devices and communications and prevent the release of toxic substances from them. It is especially important to maintain a vacuum in equipment and devices that have permanently open or leaking working openings (ovens, dryers, etc.). At the same time, practice shows that in those cases where the technology requires maintaining particularly high pressure inside the devices and in communications, knockout from such devices and communications is either not observed at all or is very negligible. This is explained by the fact that with significant leaks and knockouts, the high pressure drops sharply and disrupts the technological process, that is, it is impossible to work without proper tightness. Technological processes associated with the possibility of harmful emissions should be mechanized and automated as much as possible, with remote control. This will eliminate the danger of direct contact of workers with toxic substances (contamination of the skin, workwear) and remove workplaces from the most dangerous area where the main technological equipment is located. Timely scheduled preventive maintenance and cleaning of equipment and communications are of significant hygienic importance. Cleaning of technological equipment containing toxic substances should be carried out primarily without opening and dismantling it, or at least with minimal opening in terms of volume and time (by blowing, washing, cleaning through the stuffing box seals, etc.). It is advisable to carry out repairs of such equipment on special stands, isolated from the general premises, equipped with enhanced exhaust ventilation. Before dismantling the equipment, either to deliver it to a repair stand or to carry out on-site repairs, it is necessary to empty it completely of its contents, then thoroughly blow or rinse it until all traces of toxic substances are completely removed. If it is impossible to completely eliminate the release of harmful substances into the air, it is necessary to use sanitary measures and, in particular, ventilation. The most appropriate and gives a greater hygienic effect is local exhaust ventilation, which removes harmful substances directly from the source of their release and prevents their spread throughout the room. In order to increase the efficiency of local exhaust ventilation, it is necessary to cover sources of harmful emissions as much as possible and produce exhaust from under these covers. Experience shows that to prevent the knocking out of harmful substances, it is necessary that the hood ensure air leaks through open openings or leaks in this shelter of at least 0.2 m/sec; for extremely and especially dangerous and highly volatile substances, for greater guarantee, the minimum suction speed is increased to 1 m/sec, and sometimes more.

Acute ammonia poisoning

Ammonia (NH3) is commonly called ammonia;

it is a colorless gas with a sharp, specific odor. An aqueous solution of ammonia (10%) forms ammonia. In small quantities, this gas is generated during the rotting of nitrogen-containing substances in landfills, in the silt of rivers, lakes and swamps; found in small quantities in air and water, especially sea water. In animals and humans, its concentration is highest in the intestines; it participates in protein metabolism, which produces urea, which is excreted from the body in urine and feces. Complex compounds of ammonia with salts (ammonia oxides) are used in analytical chemistry, in the production of baking soda, nitric acid, ammonium salts, soda, anesthetic drugs, and for the separation of metals.

Ammonia

is a component of many industrial explosives (ammonals, ammonites, aquatols, aquanites, granulites, detonites, which are used in mines that are not hazardous for gas and dust). It is used in the production of dry galvanic cells, soldering, tinning, and also in medicine. Liquefied ammonia absorbs heat when evaporating, so it is used in refrigeration units.

Ammonia water and ammonium nitrate are used as nitrogen fertilizer. To enrich animal feed with nitrogen, ammoniation is carried out with ammonia water. In everyday life, gas is used as a disinfectant and bleaching agent.

Ammonia poisoning occurs through inhalation or ingestion of aqueous solutions. Upon contact with skin and mucous membranes, ammonia causes tissue burns.

At a concentration in the air of 20 mg/m3 it does not cause adverse effects on the body; poisoning occurs at a concentration of 25 mg/m3, and at a concentration of 40 mg/m3 chronic poisoning occurs.

Clinical forms of ammonia poisoning

With a mild degree of poisoning, hyperemia of the mucous membranes of the pharynx, larynx and trachea, pain and sore throat, sneezing, hoarseness, salivation, cough with the release of serous-mucous sputum appears.

The severe form is characterized by severe chest pain, production of foamy sputum, a hysterical paroxysmal cough, severe agitation, abdominal pain, and vomiting. In conditions of a burn of the mucous membrane of the respiratory tract, pneumonia, laryngeal edema, toxic pulmonary edema, and asphyxia from a reflex spasm of the larynx develop.

Contact of ammonia with the mucous membrane of the eyes is accompanied by clouding of the cornea with subsequent loss of vision. Accidental or intentional ingestion of ammonia results in sharp pain in the esophagus and stomach, and bloody vomiting. These phenomena are accompanied by disorders of the cardiovascular system, central nervous system (paresis of the lower extremities), hysterical cough, runny nose and lacrimation.

First-aid measures include stopping the flow of ammonia gas to victims and removing victims from the danger zone. You should immediately rinse your eyes with water for 15 minutes and irrigate your eyes with a 0.9% solution of table salt for 30 minutes. If ammonia gets on the skin, rinse it generously and for a long time with a stream of cool water.

Qualified medical care is required, so the victims are taken to a medical facility, where in order to prevent painful shock, painkillers are used: a 1% solution of dicaine is dripped into the eyes, and 5-10% syntomycin ointment is applied to the lower eyelid. If the victim has swallowed an ammonia solution, the stomach is urgently washed, first with cool water, then a 1% oil solution of anesthesin, protein water or milk is poured into the stomach in order to envelop the mucous membrane of the esophagus and stomach and relieve pain.

To neutralize ammonia on the skin, use solutions of citric or acetic acid. To relieve burns of the respiratory tract, inhalations of a 2% warm solution of menthol are performed. Medicines are used to suppress the cough reflex (codeine in a dosage of 0.01 g); The victims are warmed up and oxygen inhaled.

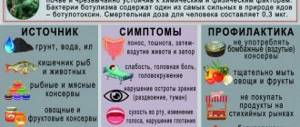

Classification and mechanism of development of food poisoning

Food poisoning is consolidated into separate etiological groups. Disorders arise against the background of the activity of microorganisms that enter human vital systems with food.

Classification of food poisoning:

- microbial nature. In practice, patients encounter salmonella, intestinal bacteria, harmful spores and streptococci. The most dangerous option: botulism and fungal fusarioses,

- nature of non-microbial origin. Poisoning with mushrooms, potato solanine, pine nuts and fish,

- illnesses of unknown etiology. In medicine, Gaffa disease and Kashin-Beck disorder occur in practice. A person's joints and limbs will have a huge number of lesions. Deforming arthrosis can lead to serious complications and transform the digestive tract.

Food must be heat treated. It will help prevent bacteria from entering the human gastrointestinal tract. Harmful microorganisms lead to inflammation of the human mucosa and the formation of ideal conditions for reproduction.

Metal aerosol poisoning (foundry fever)

The first group of occupational diseases includes foundry fever. The disease develops through systematic inhalation of metal fumes during metal casting. The type of metal does not matter (the mechanism of development of the disease and the clinical picture are similar), the fact of inhaling metal oxides - lead, zinc, copper, cobalt, nickel, mercury, silver, etc. - plays a role.

Mechanism of development of poisoning

When melted at high temperatures, metal vapors easily transform into oxides, so finely dispersed (with a particle size of 0.4-0.6 microns) that during breathing they easily penetrate into the respiratory tract up to the lungs.

In the deep parts of the lungs, they cause denaturation of cellular proteins, since metal oxide particles have enormous kinetic energy and a large electrical charge. Denatured proteins are foreign to the body and, after absorption, cause the development of foundry fever. Fever occurs in the absence of microorganisms.

Clinical picture of foundry fever

The latent period lasts 3-6 hours, after which a prodromal period begins with symptoms of weakness and fatigue.

Victims are bothered by a feeling of cold throughout the body, a severe headache, a feeling of tightness in the chest, and a cough. The appearance of severe chills indicates the onset of a true fever, when the chills last for three hours, with an increase in body temperature to 40 C. A febrile attack is accompanied by a severe headache, a feeling of aching muscles and joints; Nausea, vomiting, delirium and even loss of consciousness are added. These phenomena last 6-8 hours, then symptoms of conjunctivitis (dilated pupils), tracheobronchitis develop, and diarrhea appears with sharp abdominal pain. Reflexes increase, tremor of the fingers and tongue appears. Then the body temperature begins to drop sharply to normal levels. Such a critical drop in temperature is accompanied by profuse sweat, the person falls asleep and feels much better after sleep. However, feelings of fatigue, weakness, and weakness remain for another two to three days.

Despite the similarity of the clinical picture and mechanism of development of foundry fever, there are differences in the course of foundry fever in case of poisoning by vapors of a particular metal. Buleshov D.M. (2010) points to the predominant damage to the cardiovascular system in case of lead aerosol poisoning. If the maximum permissible concentrations are exceeded from 15.3 to 30% after 10 years of work, the proportion of practically healthy people decreases by 50%.

Nickel

translated from Latin - the name of an evil spirit that interfered with the miners and made their work difficult. It is a silvery-white metal with a melting point of 1,455°C, ferromagnetic (Curie point 358°C), resistant to water and air; up to 80% of nickel is used for alloys. This metal forms an anti-corrosion coating, therefore it is used for nickel plating of the surfaces of metal products, in the production of nickel, chromium-nickel steel, in the production of batteries, chemical equipment, for alloys with other metals, and also as a catalyst. Nickel compounds are used in the metallurgical, electrical, medical and glass industries.

Nickel enters the body through the respiratory system, upon contact with the skin of nickel salts, especially nickel carbonyl (Ni(CO4)). It irritates the skin, and in the lungs it decomposes to form carbon monoxide and nickel compounds that can form a colloidal solution in the blood; a strong general toxic effect develops, the central nervous system and protein metabolism are especially affected; Nickel accumulates in the liver, kidneys and spleen, causing the development of allergic reactions.

Signs of Nickel Poisoning

resemble the clinical picture of foundry fever, however, in case of moderate poisoning, symptoms of irritation of the upper respiratory tract are observed, manifested by a runny nose with nosebleeds, general weakness, nausea, and vomiting. When nickel compounds come into contact with the skin, “nickel scabies” develops.

When exposed to high concentrations of a toxic substance, pulmonary edema and loss of consciousness occur, then coma and convulsions develop with the disappearance of pupillary and tendon reflexes. Those affected have a gray-blue coloration of the lips, ears, nose, tongue, nail phalanges, and mucous membranes of the oral cavity. On days 3-4, yellowness of the sclera and skin develops.

Cases of chronic poisoning by nickel carbonyl have been poorly studied. The development of pneumosclerosis due to frequently recurring pneumonia, lung cancer, mucous membranes of the upper respiratory tract and paranasal sinuses was observed.

According to Karpova E. A. (2010), despite the improvement of working conditions at enterprises mining and processing chrysotile asbestos, workers first develop bronchitis, then bronchiolitis with respiratory failure due to impaired oxygen transport. In persons with connective tissue dysplasia, signs of decompensated diseases of the musculoskeletal system and cardiovascular activity quickly form.

Exposure to metal aerosols causes damage to the skin, eyes, nose, throat, and pharynx. Allergic skin diseases are also observed: epidermolysis, dermatitis, eczema, toxicoderma, urticaria, toxic-allergic hepatitis, bronchial asthma.

During the production of iron and steel, the respiratory system and gastrointestinal tract are affected.

Workers at enterprises developing deposits of ferruginous quartzites and foundries develop pneumoconiosis, cor pulmonale, chronic bronchitis with obstructive phenomena, and disorders in the pulmonary circulation.

For preventive purposes, monitoring is carried out over the sealing state of equipment, compliance with safety regulations by workers, and timely medical examinations.

First aid

- providing the victim with fresh air, creating complete rest, warming up, drinking hot coffee, tea, removing the victim from the affected area. To prevent pneumonia, antibiotics are prescribed, and to relieve an attack, the victim is placed in a warm bath.

Health care

Treatment is carried out in a hospital with prolonged inhalation of oxygen and carbogen.

BAL, unithiol and dithiocarb (BSM) are used as antidotes. If necessary, bloodletting is done followed by intravenous administration of 30-40 ml of 40% glucose solution. If pulmonary edema begins, a 10% calcium chloride solution is administered simultaneously with glucose. Antibiotics are administered to prevent pneumonia, and caffeine, cordiamine or camphor are administered to maintain cardiac activity. Measures to prevent foundry fever are outlined in the enterprise’s collective agreement. This is primarily the improvement of sanitary and technical conditions, mechanization of technological processes, and sufficient ventilation of work areas. Workers are required to use personal protective equipment to protect the skin, respiratory tract and eyes from metal fumes. After work, foundry workers must take a warm shower.

K. S. Tristen

Published by Konstantin Mokanov

Who is more likely to get infected and why?

As mentioned above, food poisoning can be of both microbial and non-microbial nature. At the same time, potentially unsafe factors may have a stronger or weaker effect on different people. What does this depend on and what are the main risk groups for potential food intoxication? Risk groups for food poisoning:

- Children . In most children of early or middle age, the gastrointestinal tract is not yet developed enough to powerfully effectively counteract bacteria, helminths, toxins and other pathogenic components of systemic acute intoxication. In this context, the consumption of the same amount of contaminated or poisoned food by an adult and a child can differ significantly - in the first it will cause only a slight illness, and in the second it will immediately cause a severe form of poisoning;

- Aged people . This category of people, especially after 60 years, has low rates of general and local immunity, as a rule, a less acidic stomach environment and other negative factors, which together significantly increase the risks of food poisoning and increase the severity of the resulting acute intoxication;

- Citizens with chronic diseases . Certain categories of patients suffering from diseases of the gastrointestinal tract, kidney or liver failure, and other chronic problems are more often susceptible to intoxication, both of a bacterial, parasitic and viral nature, and to the effects of toxic substances in the form of natural or synthetic poisons, acids and other organics;

- Pregnant women . Representatives of the fair sex in an interesting position, especially in the later stages of pregnancy, may suffer from vitamin deficiency, decreased immunity and other negative factors, as a result of which they become more susceptible to various diseases, pathologies and syndromes, in particular food poisoning. Moreover, the negative impact of certain types of food intoxication can affect not only the expectant mother, but also the fetus, forming the preconditions for abnormalities in its development.